How start-ups use laser cutting for rapid product development

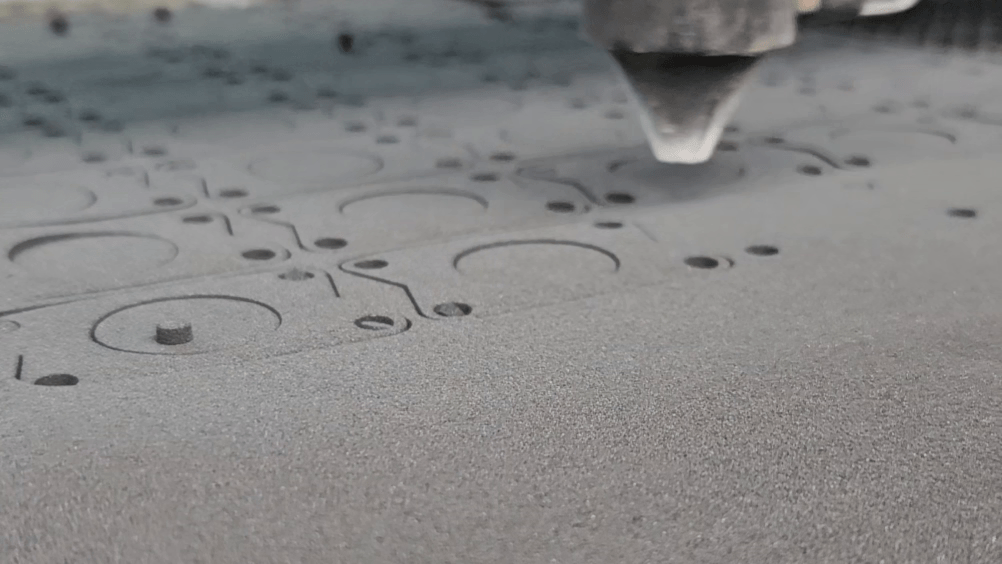

Every successful start-up begins with an idea. But an idea is nothing without execution. And in product development, one thing counts above all: speed. The time between the first sketch and a usable prototype must be short, so you can test, learn, and improve. This is precisely where laser cutting is a game changer. It offers start-ups the opportunity to quickly, affordably, and accurately move from concept to reality – without long waiting times or high entry costs.

In this blog, you will read how smart start-ups use laser cutting to accelerate their product development, why it fits perfectly within a lean working method, and how Het Laser Lokaal supports this process – without quotes, without hassle.

From sketch to cut: the power of speed

Start-ups usually don't have months to wait for a sample from an external manufacturer. They want to test tomorrow what they thought of today.With laser cutting, you can have a professional prototype in your hands within a few days. You upload your vector file, choose the right material, and see the price immediately. No quotes, no waiting lines – just submit and go.

That means:

✅ Quick turnaround

✅ Iterative improvement

✅ Minimized error margins

✅ Lower development costs

Especially in the early stages of product development, this speed is essential. You validate faster and bring better-supported products to market.

What do start-ups use laser cutting for?

Start-ups use laser cutting widely, depending on the industry.Some common applications:

Prototypes & test parts

Whether it's a casing, mechanical part, or test setup: with materials like PMMA, POM, MDF, or plywood, you can create functional parts that are immediately usable.

Front panels & interfaces

For IoT devices or electronic prototypes, laser-cut front panels are a quick way to neatly integrate buttons, displays, and sensors.

Packaging & presentation

For a pitch or crowdfunding campaign, a good presentation is essential. Laser-cut boxes, product carriers, or packaging concepts make an immediate impression.

Enclosures & final products

Some start-ups even produce their first batches with the laser – for example, clickable PET-G constructions, wooden gadget enclosures, or modular systems.

Material choice: functional and visual

The Laser Lokaal offers a wide range of materials ideal for prototypes and end-use:

-

POM (Delrin) – strong, rigid, and dimensionally stable. Suitable for technical parts.

-

PMMA - versatile plastic available in various thicknesses, finishes, and colors.

-

MDF – sleek and sturdy, good for low-cost parts.

-

Birch and poplar plywood – strong and natural, popular in product design.

-

EVA and PE foam - thick and light, good for cushioning and protection.

Because everything is digitally controlled, you can easily test variants: different holes, sizes, or shape experiments – without extra tooling costs.

No quote needed = immediate progress

What makes us unique at Het Laser Lokaal? You don't need to request a quote. Simply upload your file, choose your material, and instantly see the cost of your design to be cut. This perfectly aligns with how start-ups operate: fast, independent, and flexible.

So:

-

No delays due to email traffic

-

No minimum quantity

-

No hassle with delivery times or availability

-

Volume discount when scaling up

Want a test version tomorrow and five working models next week? No problem.

Start-ups speak: learning in layers

Many of our customers are young entrepreneurs or product designers who improve their ideas step by step.They start with a version in MDF or cardboard, test shape and fit, and then choose the right material for use or presentation.

This creates a lean development process where each version builds on the previous one – without time or budget constraints.

A customer recently shared:

“Thanks to the speed of Het Laser Lokaal, we had a test setup in hand within 48 hours. And when that worked, we immediately ordered a small series for our demo with an investor. All without having to request a single quote.”

That is exactly what laser cutting enables for small, agile teams: no obstacles, just results.

Why start-ups choose Het Laser Lokaal

Whether you're working on a smart thermostat, new educational toy, or sustainable packaging concept: with Het Laser Lokaal, you keep control in your own hands.

✅ No quote needed

✅ Fast delivery

✅ Technically suitable materials

✅ Easy to repeat and vary

✅ Volume discount when scaling up

We are also happy to think along with you about material choices or technical questions – accessible and solution-oriented.

Ready to test your idea with laser cutting?

Upload your file today and instantly discover the cost of your prototype. This way, you can make the leap from sketch to reality in one step – without delay, without risk.