Frequently asked questions about laser cutting.

What is laser cutting?

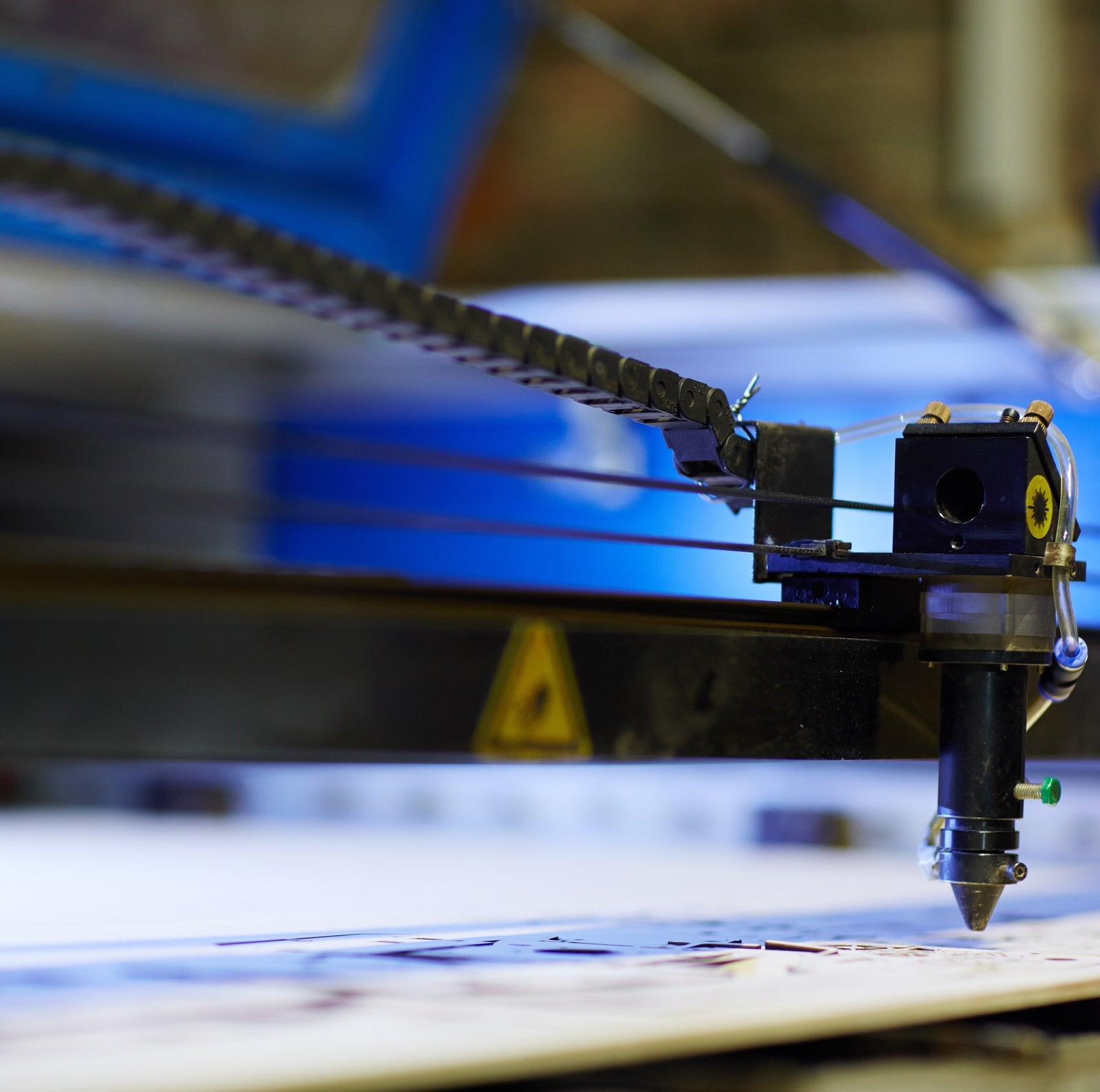

Laser cutting is the process of cutting 2D shapes from sheet material. There are different machines for various applications, but we specialize in processing wood types and plastics. Through a chemical reaction, the laser source in a laser cutter generates a thin beam of concentrated light that is directed at a small section of the sheet. This light beam is so powerful that it vaporizes a very thin cut of material.

Cutting lines perforate the material completely, allowing parts to be cut from a sheet. Depending on the material and thickness, the cut can be clean and sharp, black/brown in color, and/or leave residue. The cut is a fraction of a millimeter wider at the top of the material than at the bottom; this is almost unnoticeable with thin materials but becomes slightly more apparent with thicker materials.The costs of this operation are highly dependent on the thickness and composition of the material.

What is laser engraving?

In laser engraving, a thin layer from the top of the material is removed using the laser beam, resulting in a tangible, permanent marking on a material or product. This technique is very suitable for applying logos and markings on products or sheet material.

Laser engraving can be done in two different ways, surface engravings (filled areas) and line engravings (shallow cuts). The advantages of line engravings are that they can be executed quickly and are therefore inexpensive, while the advantages of surface engravings are that they stand out more and are more flexible regarding the information they contain (logo, text, symbols, etc.). Read more about engraving.

Frequently asked questions about designing and submitting.

A vector file is required for laser cutting. Vector files come in various formats such as EPS, DXF, DWG, SVG, AI, CDR, and PDF. We can only directly read EPS, DXF, and AI files; other vector files need to be saved in one of these formats. Read more here about what a vector file is and how to obtain one.

Our online system is flexibly developed so that templates are not necessary; you can submit your own documents. Read more here about how your drawings should be formatted.

Unfortunately, this is not possible, as these files contain 3D information instead of 2D information. If you can export your file as a 2D .DXF, .AI, or .EPS, we can use these.

The drawing will be cut as it is submitted. If you would like all parts to remain in the sheet, you can use tabs or bridges. These are small interruptions in the cutting line that ensure the material does not immediately separate.Read more about adding tabs to your design here.

This is not necessary but can be desirable in some cases, such as with spray stencils or if you want your design centered on the plate. We always align your drawing at the top right in the machine, a few millimeters from the edge.

The cut is 0.2mm for most materials. For thicker materials, the cut is slightly wider. For a tight fit, we recommend designing both parts 0.1mm larger. Materials over 6mm should be compensated by 0.15mm. Also, consider the thickness tolerance of materials.Read more about laser cutting tolerances

We can provide digital drawing and optimization work to ensure an optimal result. A submitted sketch with a description is sufficient. Contact us for the possibilities.

Frequently Asked Questions about the online portal

We ship online orders to the Netherlands, Belgium, and Germany. We can send quote requests worldwide.

Our standard production time is 4-5 working days, our fast production time is 1-2 working days (not possible for every material).When shipping, an additional 1 day delivery time is added for the Netherlands and 1-3 extra days for Belgium.

Frequently Asked Questions laser cutting & materials.

Depending on the type of cutting work, we can cut up to a maximum of 250x130cm. Most of the cutting work is done on our 130x90cm machines.

This is certainly possible, we have many materials in our assortment but can cut much more. We can also personalize products with, for example, a logo. Read more about supplying your own material here.