Laser cutting of other materials (plastics, cardboard, paper, etc.)

Laser cutting is an extremely versatile production technique. We can cut a wide variety of materials and engrave almost any material. The production technique has some unique characteristics compared to other production techniques, which - depending on the material - brings advantages and disadvantages.

Some advantages (depending on the material):

- Laser cutting provides a very fine cut with minimal material loss.

- The heat-affected zone is very small, leading to minimal thermal distortion of the product.

- The process can cut complex contours without issues, offering great design freedom.

- Laser cutting has high cutting speeds, up to 20 cm/sec, depending on the material thickness and type.

- The result is a straight, burr-free cut with a smooth surface.

- In most cases, no post-processing is needed, such as polishing.

-The process is precise, with a positioning accuracy of ± 0.1 mm.

-It is a non-contact operation, allowing for easy clamping of the product.

-It is flexible and can cut many types of materials with varying thicknesses.

-It is possible to quickly switch to another product.

Some (possible) disadvantages:

-Different material structures can arise due to the heat-affected zone, which can lead to adverse properties such as hardening phenomena, cracking, and reduction of material strength.

-At a too slow cutting speed, the cut can burn out (this is often the limiting factor concerning thickness).

-The cutting edge of a laser-cut product is not exactly perpendicular because the beam diverges (widens) when it burns into the material.

-Although the cutting loss is minimal, it is still approximately 0.2mm.The consequence of this is that compensation must be made for this in, for example, tight connections.

-Depending on the material, the maximum thickness of the sheet is approximately 10mm.

What materials can be laser cut?

There are many factors that play a role in whether a material can be cut. Usually, the easiest way to determine if a material is suitable for cutting is to test it in the machine, but you can already reasonably assess whether a material is cuttable by considering the following points:

-In principle, only flat sheet material can be cut, as the material must lie flat in the machine.

-Most materials thicker than 12mm cannot be cut (exceptions to this are Plexiglas and materials with an extremely low density such as foam).We do not cut materials that are dangerous (such as those containing PVC) and materials that inherently cannot be cut, such as glass, steel (though possible with other types of laser cutters), and carbon-containing sheet materials.

-The thinner the material, the better the result will be, as the laser beam has to remove less material. For organic materials like wood, this also means less soot on the cut. Materials with high density or thermoplastics (PP, HDPE, Nylon) partially melt back together after laser cutting.

Below is a brief summary of different materials we can cut, along with their maximum thicknesses and cuttability. This table is not exhaustive; if you are unsure about your material, feel free to contact us.

| Material | Maximum thickness | Cutting ability |

| Birch plywood | 6mm | Good |

| Okoume plywood | 4mm | Moderate, a lot of charring |

| Plywood Poplar | 12mm | Good |

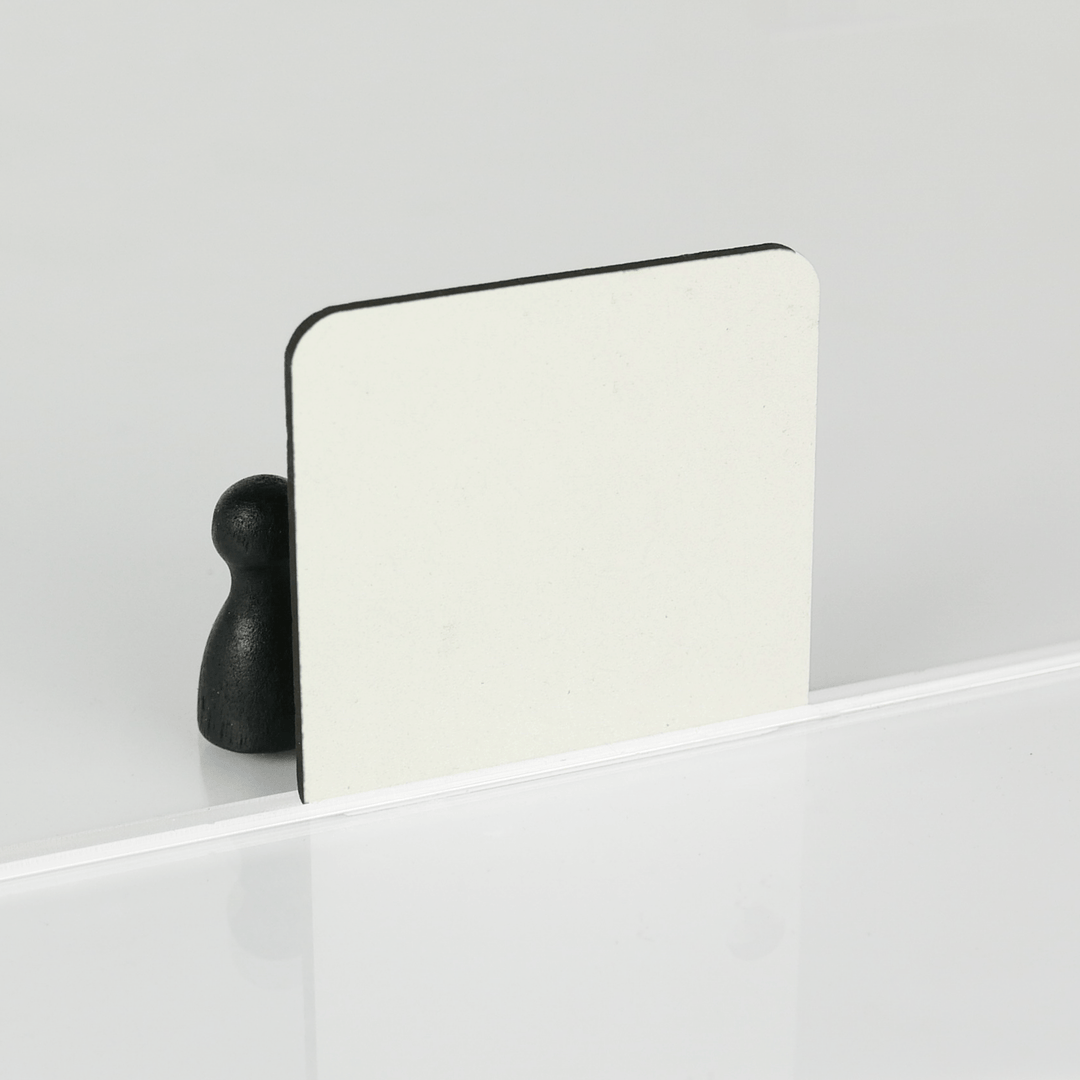

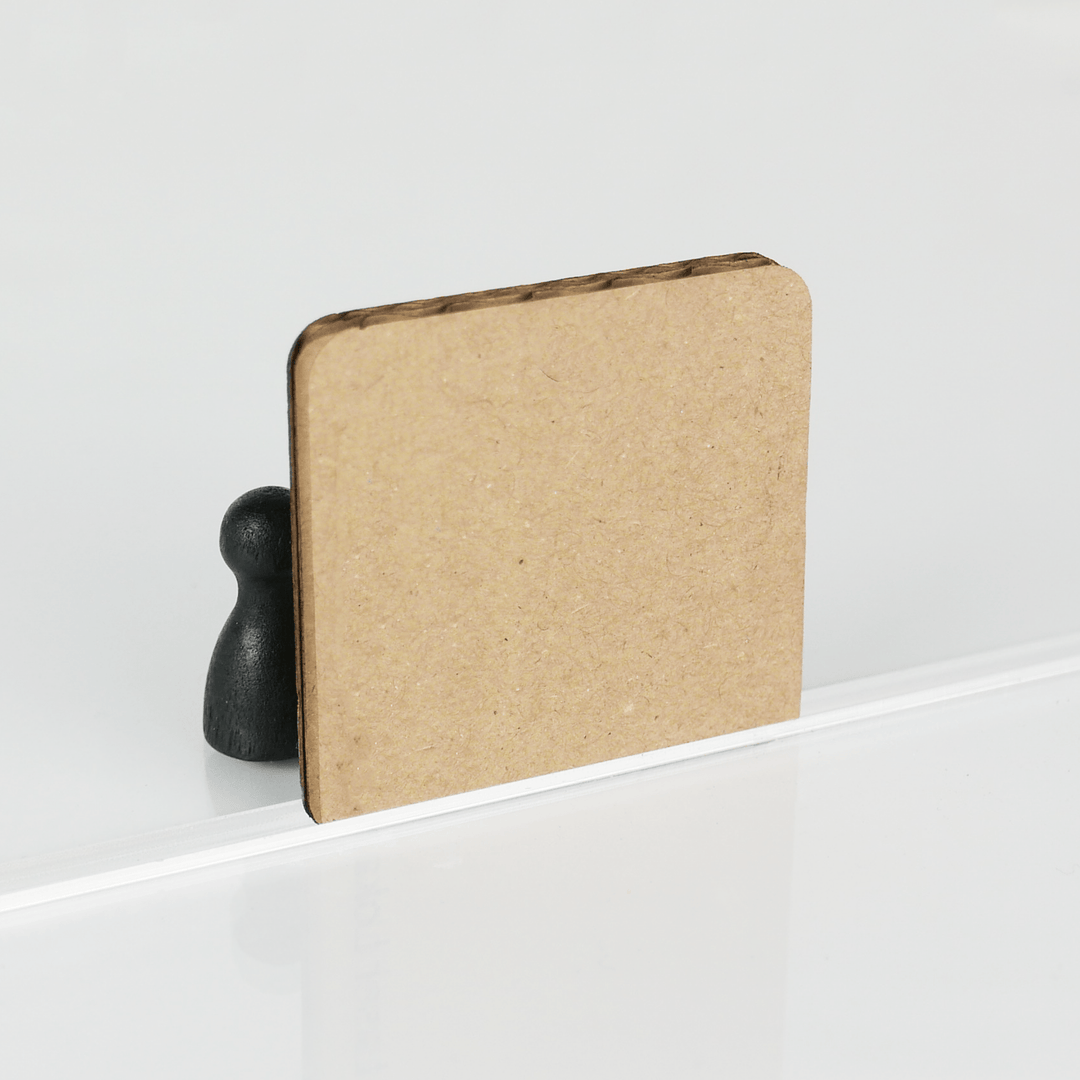

| MDF | 12mm | Very good |

| Plexiglass, PMMA | 18mm | Very good, clean cut |

| Thermoplastics (Nylon, HDPE etc.) | ~5mm | Moderate, cut melts back together |

| Cork | 3mm | Good |

| Textile (polyester) | n/a | Very good |

| Textile (cotton) | n/a | Moderate, brown edges |

| Epoxy/fiberglass | x | Impossible, extreme charring |

| Glass | x | Impossible |

| Paper/cardboard | various | Moderate |

| Leather | 2mm | Moderate |

| Rubber | various | Good, depending on type |

| Foam | 50mm | Good, depending on type |

| Steel/metals | x | Not possible |

Which materials can be engraved?

Almost any material can be engraved, such as metals, wood, plastics, and much more.The finish of the engraving depends on the material. For example, engravings on acrylic become matte white, and engravings on birch plywood become dark brown.

A major advantage of engraving is that it can also be done on objects, as long as they have a (reasonably) flat side. The only materials we do not engrave are those containing PVC (vinyl, Skai leather, etc.), thin materials with low density (such as thin textiles) are difficult to engrave. Also, round or convex objects are difficult or sometimes impossible to engrave.

Lees meer