Laser cutting of technical plastics

In precision work, material choice is crucial. Therefore, Het Laser Lokaal offers a carefully selected collection of technical materials that excel in functionality, durability, and laser workability. These materials are specifically suitable for applications where properties such as strength, dimensional stability, heat resistance, or low-friction operation are essential — for example, in product development, machine construction, robotics, or industrial design.

In this collection, you will find plastics such as POM and PET-G, as well as rubber-like materials each with their own specific advantages. Discover below the properties, applications, and benefits of each technical material in our assortment.

What are technical materials?

Technical materials distinguish themselves from decorative or natural materials by their functional performance.Consider high tensile strength, wear resistance, chemical resistance, temperature resistance, or a low coefficient of friction. These properties make them ideal for mechanical parts, prototypes, seals, or structural elements.

Our technical materials are optimally suited for laser cutting or engraving, which means they produce clean cut edges and precise details without mechanical stress on the workpiece. This makes them extremely suitable for technical drawings, assembly parts, or custom components.

Overview of technical materials in our range

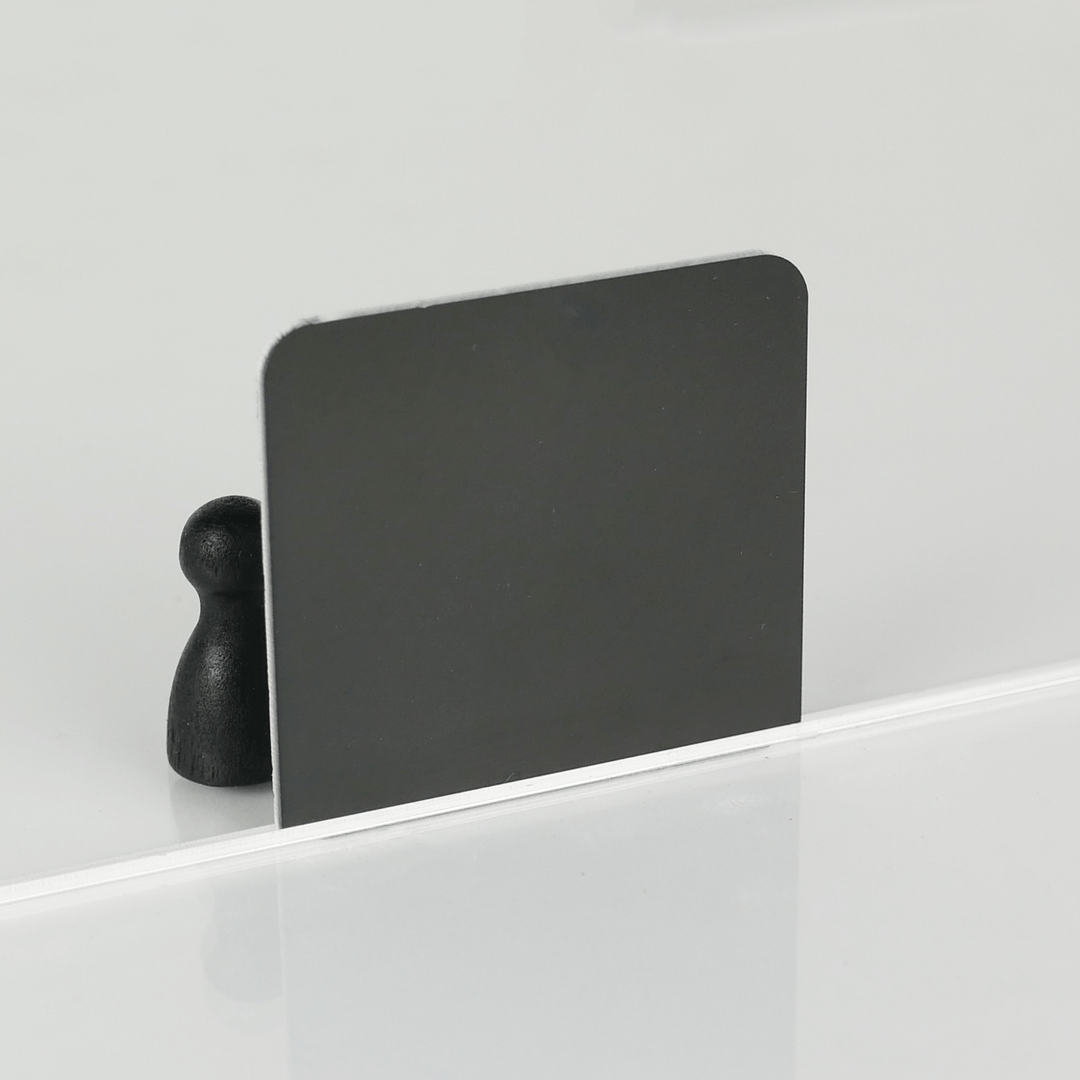

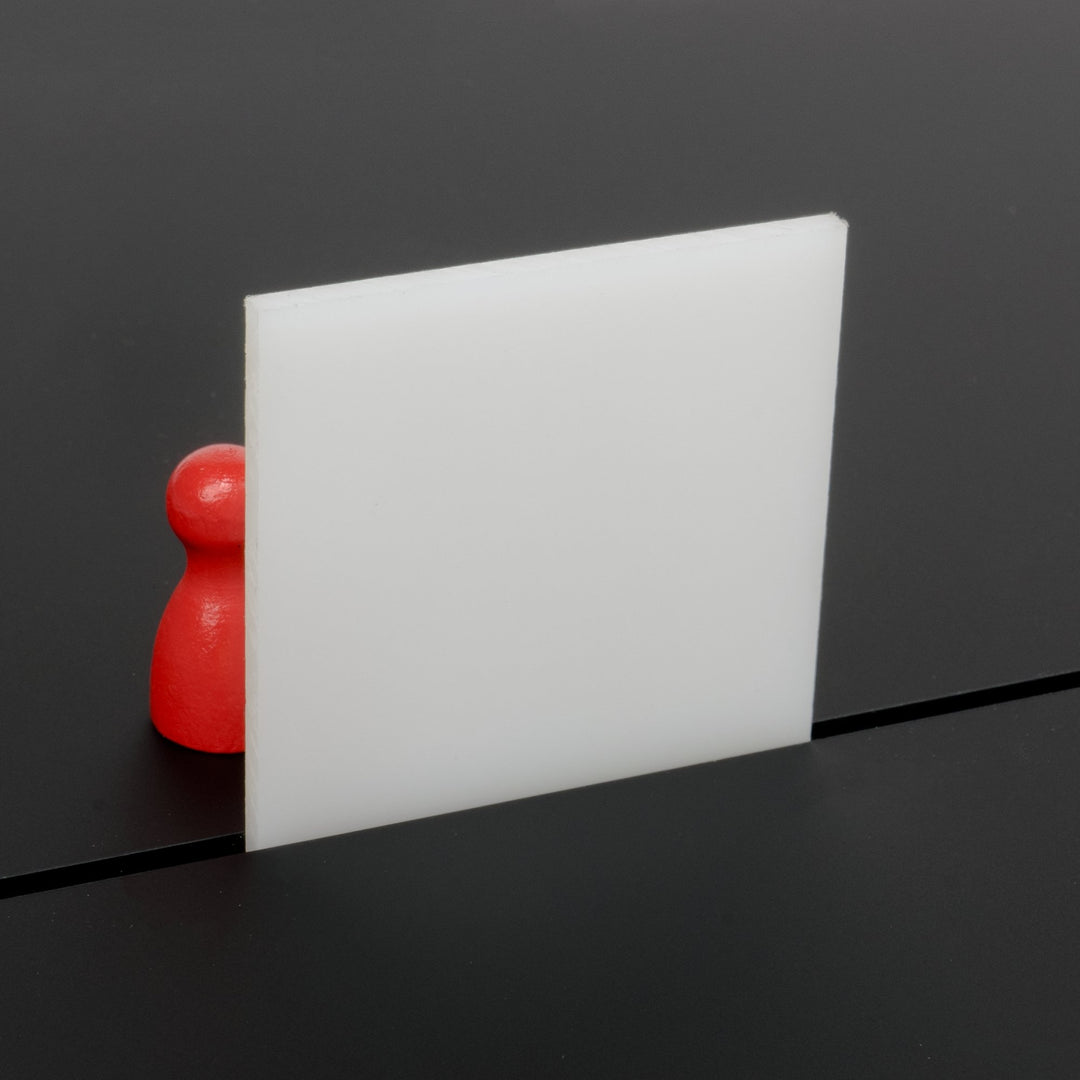

1. POM (Polyoxymethylene)

Properties:

POM is an engineering plastic with excellent mechanical properties. It is rigid, dimensionally stable, wear-resistant, and has low friction resistance.Thanks to its stability under load, POM is often used as an alternative to metal in technical applications.

Applications:

-

Gears and bearings

-

Housings for electronics

-

Precision parts for machines

-

Movable joints or sliders

Why laser cutting in POM?

POM can be laser cut very precisely, which is ideal for complex contours. The material retains its structure and dimensions without distortion or melting with correct settings.

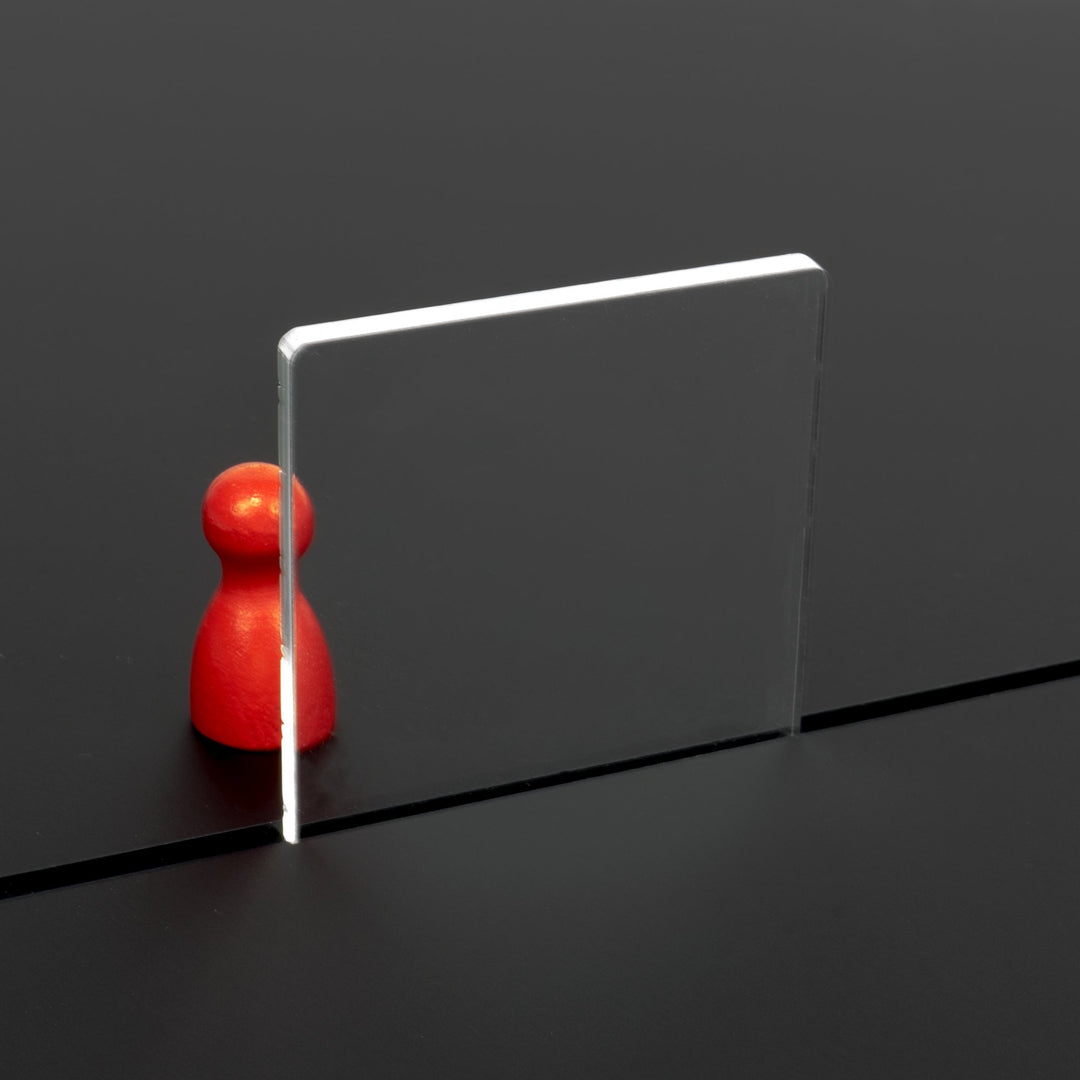

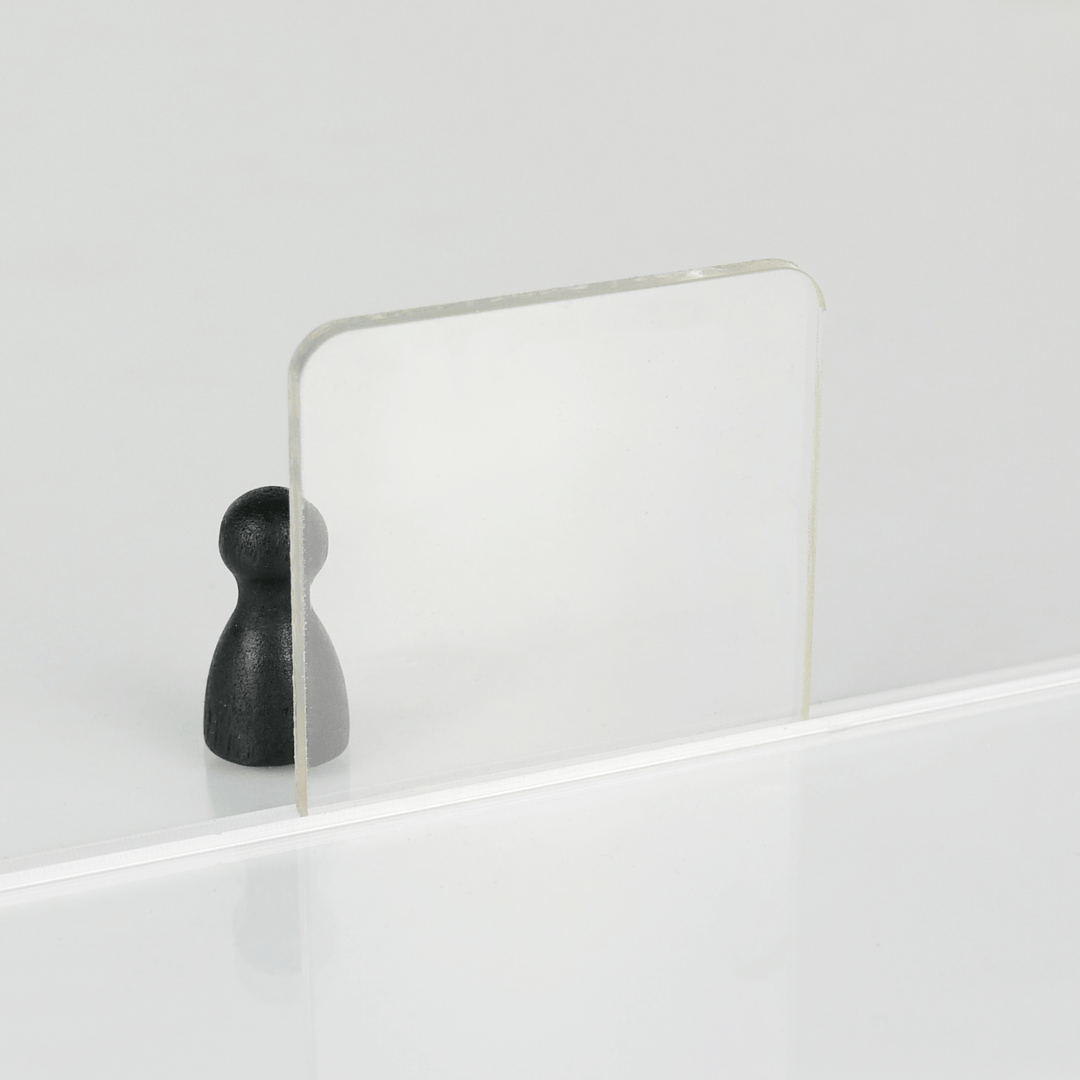

2. PET-G (Polyethylene terephthalate glycol-modified)

Properties:

PET-G is a transparent, strong plastic that is resistant to chemicals and impacts. It is less brittle than acrylic, and therefore has better impact resistance.PET-G is often used as a substitute for glass or plexiglass in technical applications.

Applications:

-

Transparent shields

-

Technical prototypes

-

Enclosure panels

-

Displays and functional models

Why laser cut in PET-G?

PET-G cuts sharply and produces relatively little smoke. The edges are slightly colored after cutting but maintain a smooth surface. Engraving is limited.

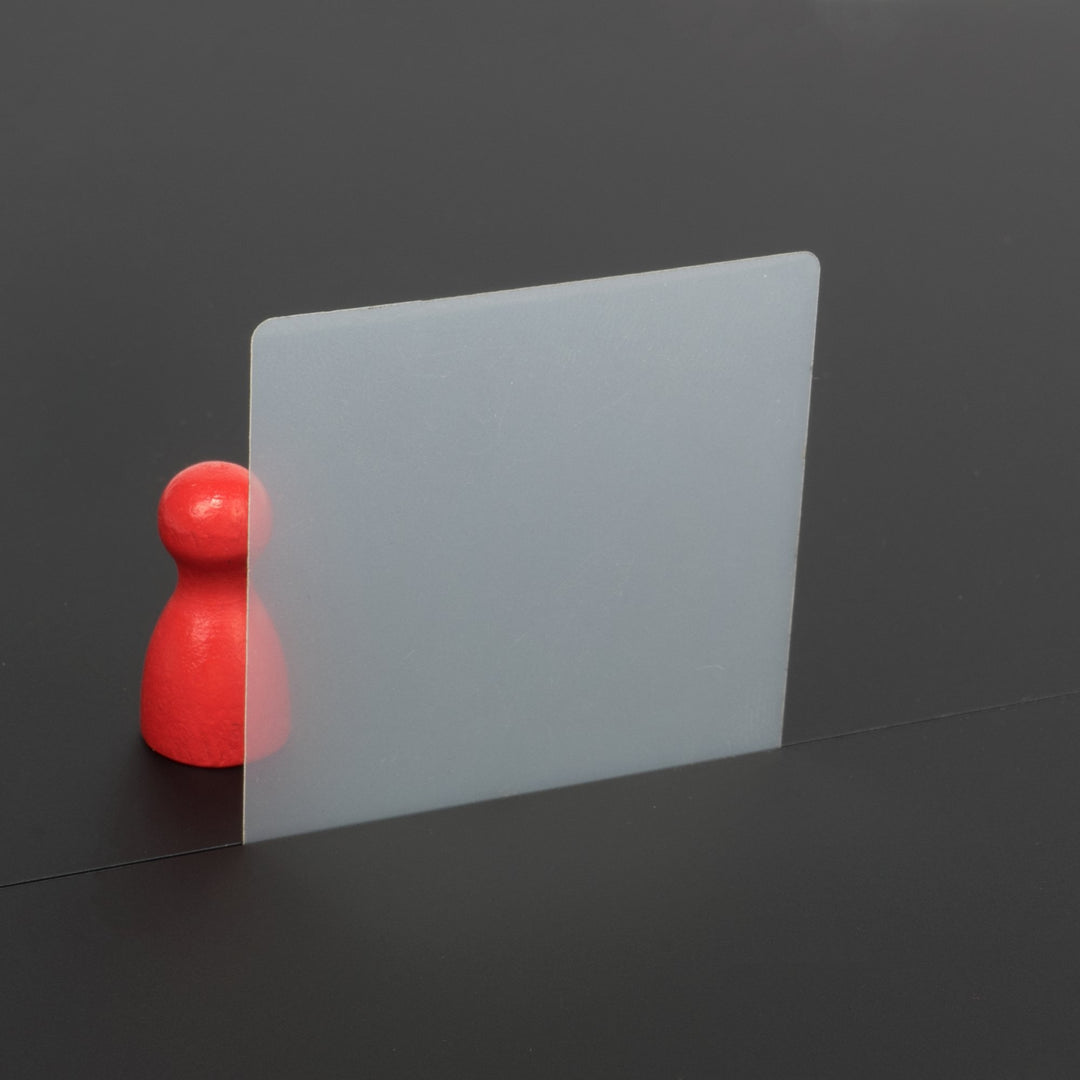

3. Rubber and rubber-like materials

Properties:

Rubber materials such as laser-compatible neoprene or silicone rubber are elastic, pressure-resistant, and resistant to water or chemicals. They are widely used for functional parts such as gaskets and seals.

Applications:

-

Seals and gaskets

-

Vibration dampers

-

Anti-slip mats

-

Protective layers and pads

Why laser cut rubber?

Laser cutting allows for the production of complex shapes with small tolerances, which is particularly important for gaskets or flexible parts. Note: not all types of rubber are suitable for laser cutting — we only offer materials that are safe and clean to cut.

Why choose technical materials from Het Laser Lokaal?

At Het Laser Lokaal, we combine high-quality materials with a fast, accessible service.Our technical materials are:

-

Directly available online, with clear pricing and material specifications

-

Perfectly suited for laser cutting, tested in our workshop

-

Suitable for functional prototypes and end-use applications

-

Available in multiple thicknesses and formats, allowing you to design efficiently

Additionally, you benefit from direct volume discounts, fast delivery times, and expert guidance on technical questions. Our goal is to bring your technical ideas to a professional end result as quickly as possible — whether it's a single part or a complete series.

Common applications of technical materials

Our customers use these materials for, among other things:

-

Mechanical parts and assemblies

-

Educational models for technical education

-

Enclosures and test setups for electronics

-

Interfaces and panels for industrial equipment

-

Moving parts in product prototypes

Because laser cutting is contactless, no mechanical stresses are introduced into the material. This ensures that the dimensions remain extremely precise — crucial in technical designs.

Ready to get started?

Our collection of technical materials provides a reliable foundation for anyone working on technical designs, functional prototypes, or industrial applications.Whether you work as a product designer, mechanical engineer, technician, or R&D professional: with the right material properties and laser cutting quality, you make the difference.

Lees meer