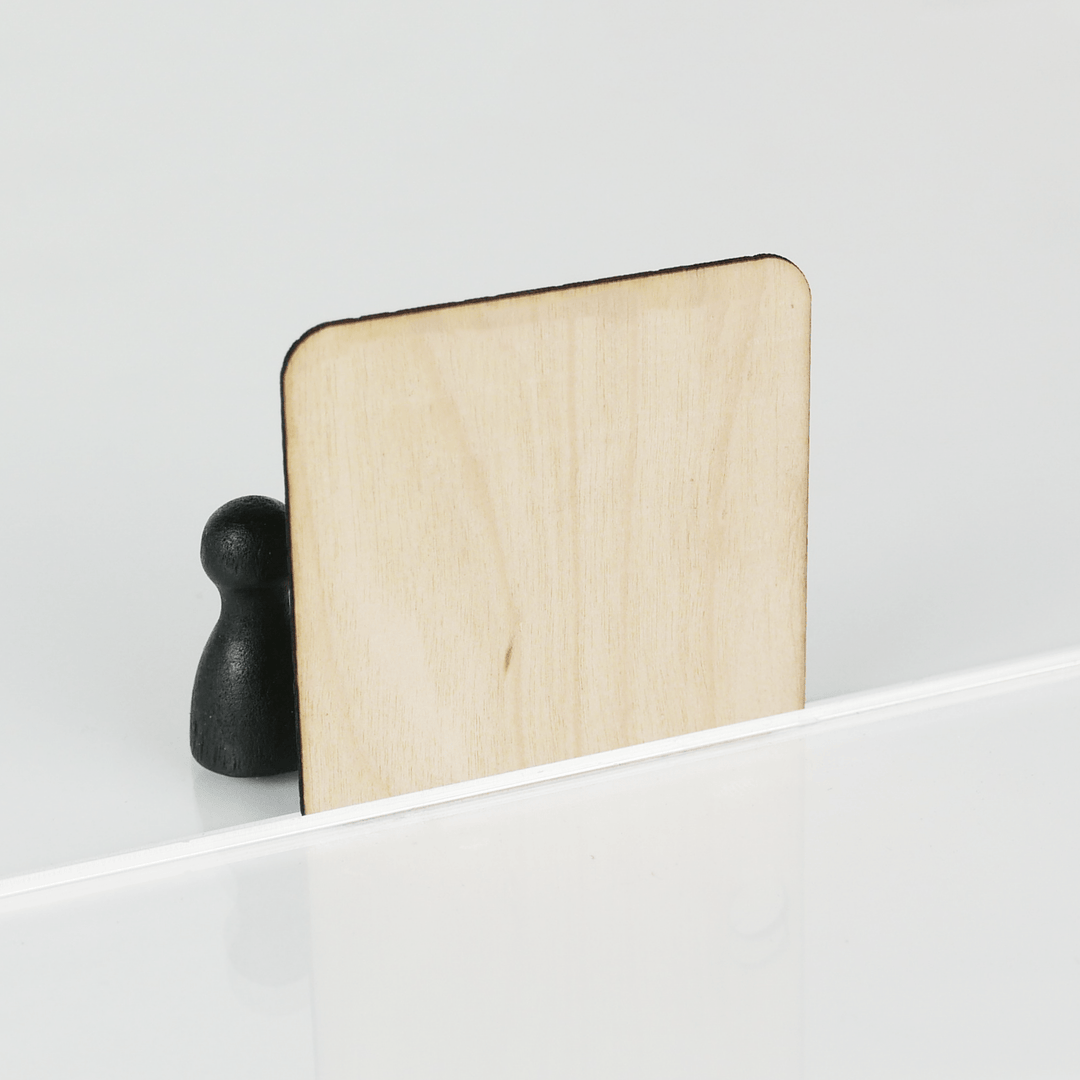

Birch aircraft plywood is a flexible all-round sheet material composed of 3 thin layers of birch veneer. The material is sturdy and light in color. We supply B/B quality plywood, meaning that both sides are virtually flawless.

Applications

Birch aircraft plywood is used for applications that require (light) flexible wood such as (scale) model building and maquettes, and applications in the field of thin sheet material such as paneling and furniture and interior construction.

Design Considerations

Pay attention to the thickness tolerance when designing finger and slot joints. Birch plywood has a grain direction, which is generally horizontal on a full sheet, but can also be vertical depending on how the sheet is cut. If the grain direction is important, it must be specified in advance.The sheets are bendable in the cross-grain direction (bending direction over the short side t.o.v. 120x60cm sheet).

Laser Cutting

The cut edges of birch aircraft plywood are black and may leave a slight residue. On the top and bottom sides of the material, there will be smoke residue around the cut, this can largely be prevented by using protective film. Any remaining smoke residue on the material can be easily removed with sandpaper.

| Cutting Width |

0.2mm (±0.05mm)

|

| Smallest Included Shape |

6x6mm |

| Smallest Detail (engraving) |

1mm |

Maximum Size

|

120x60cm (up to 153x130cm possible on request) |

| Additional Options |

Double-sided adhesive film, protective film top/bottom |

Post-processing

Post-processing of birch aircraft plywood is not necessary; however, the sheet material can be sent with 400 grit sandpaper for a smooth finish. Birch plywood can be painted, glued, sawn, drilled, and sanded, either afterwards or beforehand.

Appearance

Birch aircraft plywood is very light brown in color, with black cutting edges and surface and line engravings that may slightly rub off. Each sheet is almost entirely flawless on the front, while the back may have slightly more knots and plugs. Due to the production process, the density may vary slightly. The sheets may warp slightly or not be completely straight due to their thickness.

Technical Information

Property

|

Value |

| Density |

0.9 grams / cm3 |

| Thickness Tolerance |

<10% |

| Suitable for Outdoor Use |

No |

Delivery Time: Delivery possible from 1-2 working days