Laser cutting wood

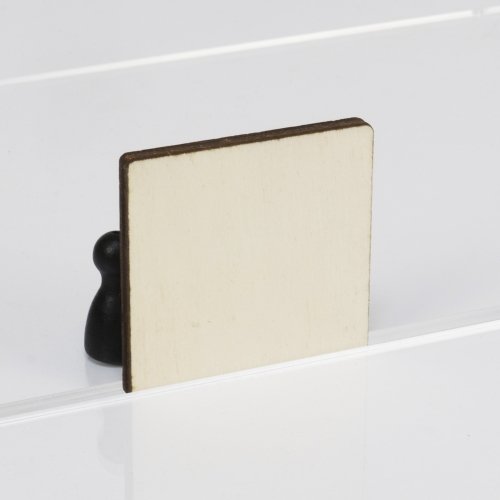

Laser cutting is a technique that uses a laser beam to precisely cut through various materials. Plywood, MDF, and other types of wood are materials often used in laser cutting. When cutting wood, lasers can produce a wide range of shapes and sizes, from simple geometric shapes to intricate patterns and engravings.

Plywood laser cutting

One of the main advantages of plywood, MDF, and other types of wood is their versatility. The material can be cut and engraved with a laser into all sorts of shapes and patterns. This makes it ideal for creating personalized items such as nameplates, keychains, and wooden decorations. Whether it's for a sleek modern style or a more rustic look, plywood can meet almost any design requirement.

Additionally, there are multiple types of wood to choose from, such as MDF, poplar, birch, and okoume. Poplar plywood is lightweight and has a fine texture, making it easy to cut and engrave. Birch plywood has a beautiful natural appearance and is perfect for projects that require a warm atmosphere. Okoume plywood has a pinkish color and is very suitable for humid applications. MDF is a budget wood type for prototypes and constructive purposes.

Advantages of wood laser cutting:

- High precision: Laser engraving provides very detailed and accurate cuts, even on small shapes. The laser beam removes approximately 0.2mm of material. The result is a clean cut with minimal loss

- Contactless process: Since the laser does not physically touch the material, there is less chance of shifts.

- Minimal post-processing: Due to the high quality of laser-cut parts, they are ready for use directly from the machine. Post-processing is not required.

- Large scalability and high degree of reproducibility. This is especially useful for companies offering personalized items, as they can ensure consistency in their products.

Wood laser engraving

One of the main advantages of wood laser engraving is the precision it offers. The laser head moves with low power over the surface of the wood, allowing even the smallest details to be engraved accurately. This means there is less breakage and cutting errors, as the engraving is contactless. Moreover, no post-processing is needed after engraving, saving time and costs. Additionally, wood laser engraving is efficient and fast. This makes it an ideal choice for companies that need to produce large quantities of products.

It can be used to personalize a wide range of items, from corporate gifts and business cards to signposts and serving boards. Additionally, it can be used to engrave barcodes, texts, logos, QR codes, and images into wood. Regarding the costs, the price for wood laser engraving varies depending on several factors, such as the design, complexity, and quantity.

There are 2 types of engravings possible: surface engraving and line engraving. Line engravings are essentially shallow cuts into the material, while surface engravings are shallow filled areas on the front of the material. Here you can read more about line engraving and surface engraving.

Wood Types Laser Cutting at Het Laser Lokaal

We offer from our own stock a wide variety of wood types such as (black) MDF, Poplar plywood, Okoume multiplex, Birch plywood, and hybrid types like Vibers. Upon request, we can supply many more types and it is also possible to provide your own (solid) wood.

Our largest laser machine is capable of cutting wood sheets up to a maximum size of 250 x 130 cm and up to 12mm thick in any conceivable shape. This allows us to produce custom-made wooden products of the highest quality, either in series or as unique design objects. Suitable for applications in advertising, signage, interior design, or exhibition construction.

Wood laser cutting service

Do you have a question, idea, or ready-made project in the field of laser cutting? We are happy to assist you! Please contact us, request a quote or if you have a cutting design that meets our drawing rules you can upload and order it directly via our online portal.

Lees meer