Mirror acrylic (PMMA) has a mirrored surface on one side and reflects light just like a normal mirror. In addition, the material is lighter than a glass mirror, what the material a excellent replacement for a glass mirror.

Applications

Mirror acrylic Acrylic has many applications, mainly in decorative industries. Acrylic can be found in showcases, interior construction, displays, facade advertising, (name) signs and models.

Because the material has a high impact resistance and is 25x stronger and 50% lighter than glass, it is often used as a replacement for glass.

Design considerations

There are few restrictions when cutting acrylic. When using finger joints, it is important to take into account the thickness tolerances of acrylic to prevent internal stresses and thus cracks or breaks. Acrylic is also relatively fragile in thin or long strips and is sensitive to warping due to the heat released during cutting, so take this into account in your design.

Laser cutting

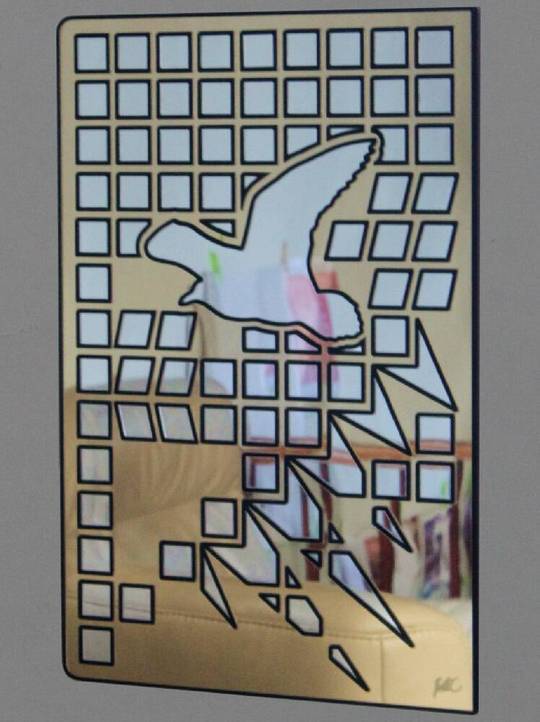

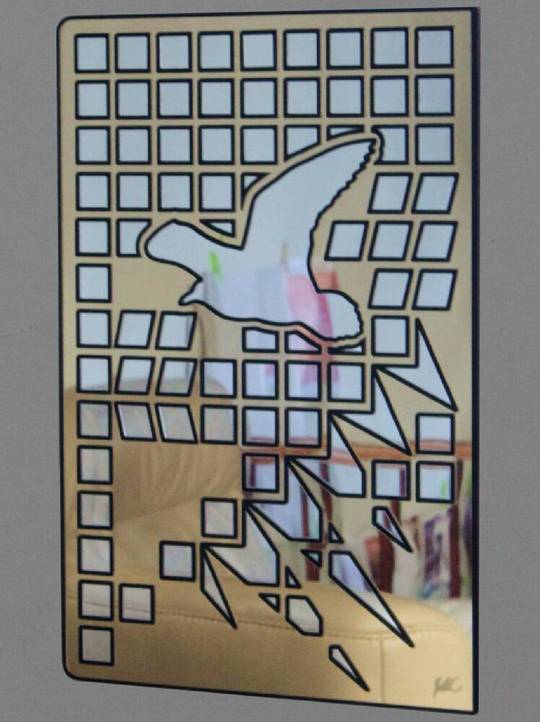

Acrylic mirror has a protective film on the front, which means the mirror is fully protected before, during and after cutting. The cut is tight, clean and the same colour as the material. Engraving areas have a slightly whiter colour compared to the material.

If there are line or surface engravings in the design, the complete design will be cut and engraved in mirror image on the back (the design does not need to be printed for this). to be put in mirror image, we do this). Engravings are done as standard on the back of the mirror in mirror image to prevent reflection of the engraving. Engraving on the front is also possible, this gives a small 3D effect because the engraving is also reflected.

| Cutting width | 0.2mm (±0.05mm) |

| Smallest shape supplied | 6x6mm |

| Smallest detail (engraving) | 1mm |

| Maximum size | 120x60cm (up to 250x130cm is possible on request) |

| Additional options | Double-sided adhesive foil |

Post-processing

In principle Acrylic does not require post-processing due to the high quality of the material. The material can be glued, printed, sawn, sanded or milled afterwards and bent. With every operation it is important to take into account that the cutting process puts pressure on the cutting edge, if the acrylic is then processed then in some cases small cracks can occur.

To give line and surface engravings a greater contrast, they can be filled with paint (color fill). When the excess paint is then removed, the paint remains in the grooves.

Appearance

The material always has a protective film on the front, the back lacks a protective film. Engraving lines and surfaces are engraved from the back (in the mirror layer). The material is scratch-sensitive without a protective film.

Mirror acrylic reflects like a normal mirror, surface and line engravings have a matt white appearance and a little bit of a 3D effect. All parts are firmly packed in a box and, if necessary, supported with wood.

Technical information

| Characteristic | Value |

| Density | 1.2 grams/cm3 |

| Thickness tolerance | <15% |

| UV resistant | Yes |

| Type acrylic | Cast |

Delivery time: Delivery possible within 1-2 working days

Technische gegevens van Acrylic Mirror Silver

| Voordelen | Licht en breukveiliger dan glas, hoog spiegelrendement, strak te lasersnijden, goed te graveren aan de achterzijde voor logo’s/tekst, eenvoudig te monteren, onderhoudsarm |

| Nadelen | Krasgevoeliger dan glas, achtercoating kan beschadigen bij ongeschikte lijm/reiniging, lichte vervorming/“funhouse”-effect bij grote platen op niet-vlakke ondergronden |

| Goed geschikt voor | Interieurdecoratie, displays en signage, beurzen en retail, props en kunstobjecten, kindvriendelijke spiegeltoepassingen, lichte bekledingen |

| Minder goed geschikt voor | Optische precisietoepassingen, langdurig buitengebruik zonder bescherming, sterke kromming/buiging, situaties met intensief schurend contact |

| Beschikbare kleuren | Zilver |

| Beschikbare diktes | 3mm |

| Grootste standaard maat | 120x60cm |

|

Grootste maat op aanvraag

Heb je een project wat groter is dan onze standaard maat?

Vraag een offerte aan. |

120x242cm |

| Snede breedte | 0,2mm |

| Kleinst mogelijke detail (graveren) | 1x1mm |

| Kleinste meegeleverde vorm | 6x6mm |

| Speciale kenmerken | Spiegelend |

| Geschikt voor buitengebruik | Nee |

| Dichtheid | 1,2 g/cm³ |

| Lichtdoorlatendheid | Ondoorzichtig |

| Diktetolerantie | 5% |

|

Beschermfolie

Lees hier meer over

beschermfolie.

|

Standaard voorzijde, niet mogelijk achterzijde |

|

Dubbelzijdige plakfolie

Lees hier meer over

dubbelzijdige plakfolie.

|

Optioneel aan de achterzijde |

| Type materiaal | Acrylaat gegoten (GS) |

| Oppervlakte voorzijde | Matte grijze backing |

| Oppervlakte achterzijde | Glad, glanzend |

| Levertijd | Direct uit voorraad leverbaar |

Sample nodig?

Bestel een sample om materiaal, kleur en afwerking in het echt te beoordelen.

Psssttt....

Losse materialen bestellen?

Wist je dat je onze materialen ook zonder bewerking kan bestellen om zelf te lasersnijden? Neem gauw een kijkje bij Laser Cut Supply.