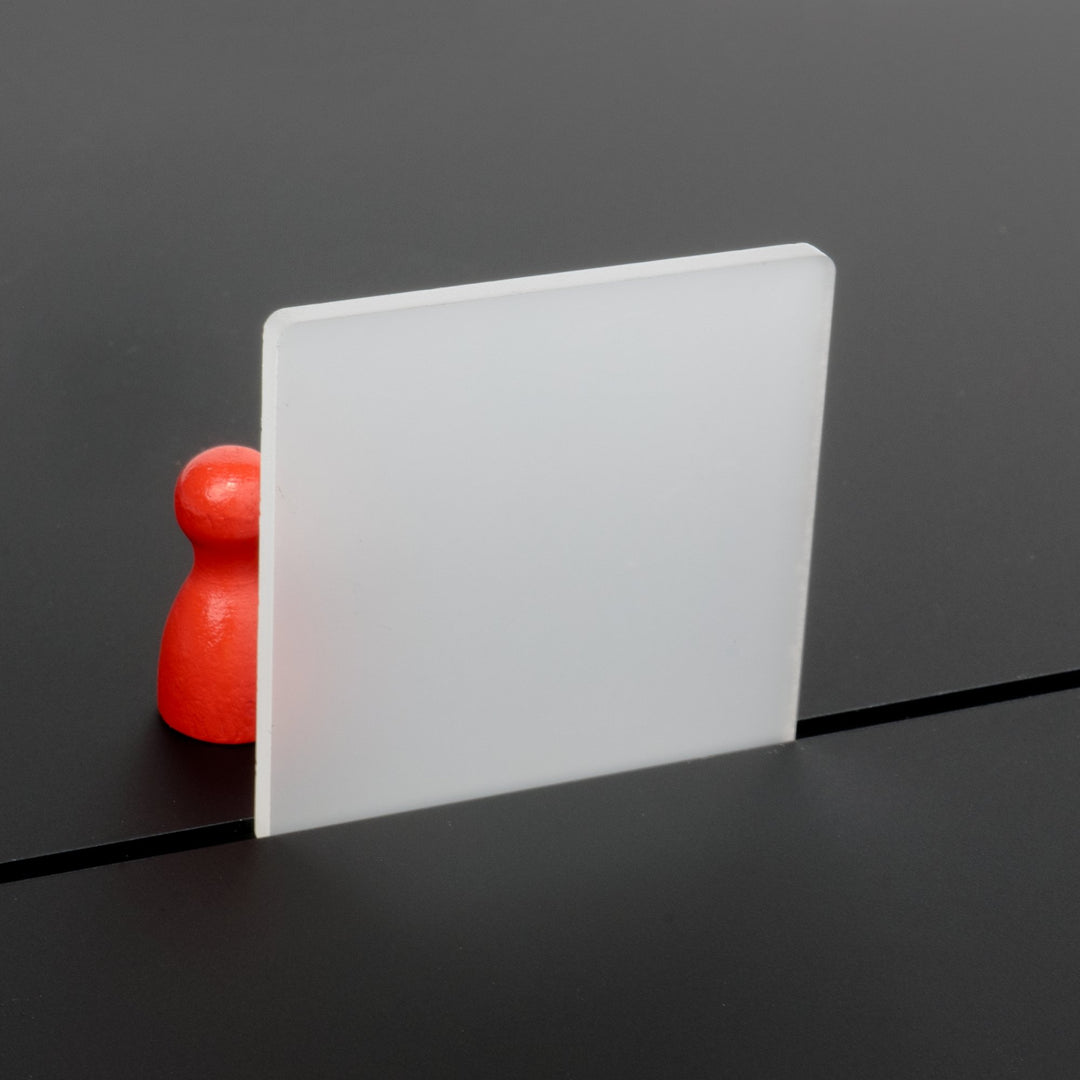

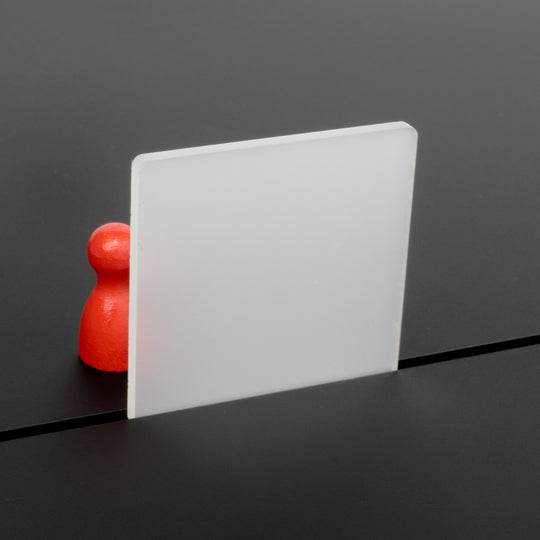

Light opal acrylic (PMMA), also known by the brand names Plexiglas and Perspex, is a hard, translucent plastic. The material is UV resistant and suitable for both indoor and outdoor use. The material is not transparent, but allows enough light to pass through that the shapes of objects are visible. Light opal Acrylic is also known as privacy acrylic.

Applications

Light opal acrylic has many applications, mainly in decorative industries. Tinted acrylic can be found in showcases, interior construction, displays, facade advertising, (name) signs and models.

Because the material has a high impact resistance and is 25x stronger and 50% lighter than glass, it is often used as a replacement for glass.

Design considerations

There are few restrictions when cutting acrylic. When using finger joints, it is important to take into account the thickness tolerances of acrylic to prevent internal stresses and thus cracks or breaks. Acrylic is also relatively fragile in thin or long strips and is sensitive to warping due to the heat released during cutting, so take this into account in your design.

Laser cutting

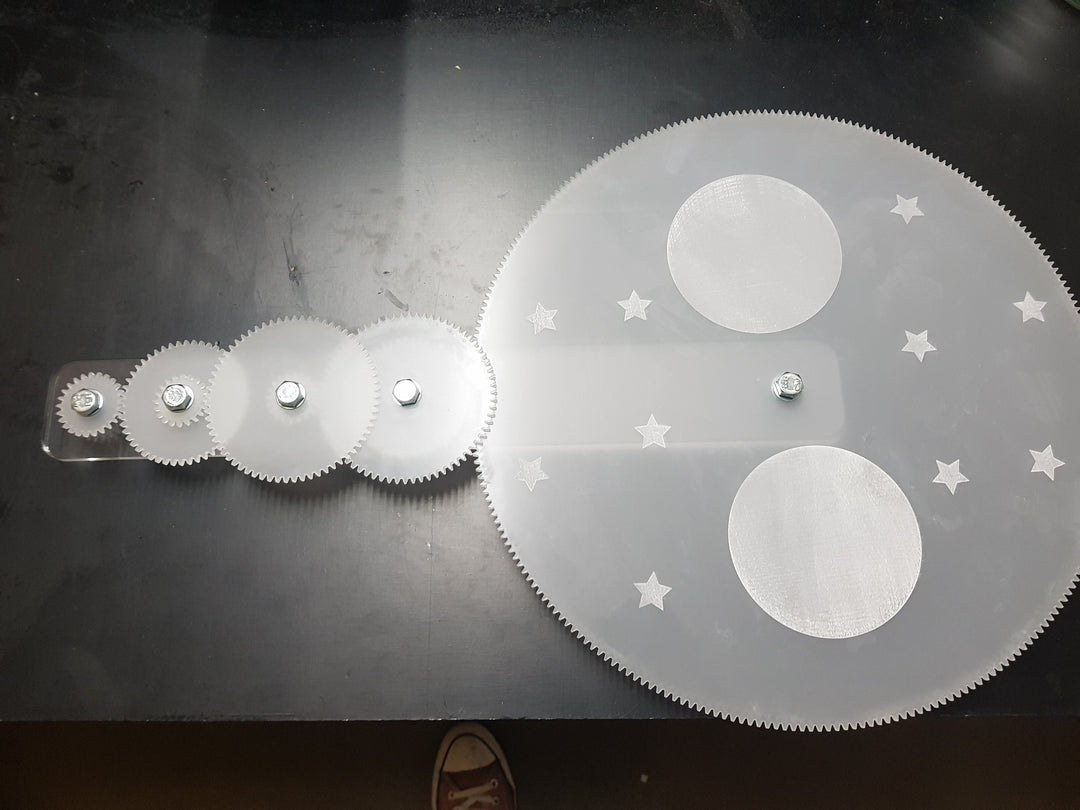

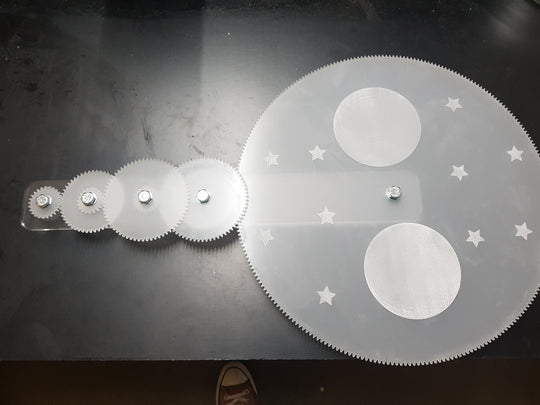

Acrylic has protective film on both sides, which means the plates are fully protected before, during and after cutting. The cut is tight, clean and the same colour as the material. Engraving areas have a slightly whiter colour compared to the material.

If there are only cutting and engraving lines in the design, we leave the foil on both sides. If there are engraving areas in the design, we must remove the foil from the top, in some cases a small amount of smoke can then affect the material.

Post-processing

In principle Acrylic does not require post-processing due to the high quality of the material. The material can be glued, printed, sawn, sanded or milled afterwards and bent. With every operation it is important to take into account that the cutting process puts pressure on the cutting edge, if the acrylic is then processed then in some cases small cracks can occur.

To give line and surface engravings a greater contrast, they can be filled with paint (color fill). When the excess paint is then removed, the paint remains in the grooves.

Appearance

Depending on whether there are engraving areas in the design does the material have protective film on both the front and back or only the back. The material is scratch-sensitive without protective film.

Light opal acrylic has a light surface gloss and is translucent. Flat engravings have a matt white appearance, engraving lines are clearly visible from close up. All parts are securely packed in a box and, if necessary, supported with wood.

Technical information

| Characteristic | Value |

| Density | 1.2 grams/cm3 |

| Thickness tolerance | <15% |

| UV resistant | Yes |

| Type acrylic | Cast |

Delivery time: Delivery possible within 1-2 working days

Technische gegevens van Light opal Acrylic (Translucent)

| Voordelen | Zachte, gelijkmatige lichtverspreiding, vermindert verblinding en reflecties, UV-bestendig, vormvast en duurzaam, strak te lasersnijden, onderhoudsarm |

| Nadelen | Minder doorkijk dan helder acrylaat, fijne details achter het materiaal minder zichtbaar, dunne of smalle delen gevoeliger voor warmteinwerking |

| Goed geschikt voor | Diffusers, privacy-panelen, stijlvolle verlichting, ontwerpdetails, interieurtoepassingen |

| Minder goed geschikt voor | Transparantie-toepassingen waar helder zicht vereist is, dragende structuren, zeer dunne of stressgevoelige onderdelen |

| Beschikbare kleuren | (Melk)wit |

| Beschikbare diktes | 3mm |

| Grootste standaard maat | 120x60cm |

|

Grootste maat op aanvraag

Heb je een project wat groter is dan onze standaard maat?

Vraag een offerte aan. |

120x242cm |

| Snede breedte | 0,2mm |

| Kleinst mogelijke detail (graveren) | 1x1mm |

| Kleinste meegeleverde vorm | 6x6mm |

| Geschikt voor buitengebruik | Ja |

| Dichtheid | 1,2 g/cm³ |

| Lichtdoorlatendheid | Translucent |

| Diktetolerantie | 10% |

|

Beschermfolie

Lees hier meer over

beschermfolie.

|

Beide zijden standaard voorzien |

|

Dubbelzijdige plakfolie

Lees hier meer over

dubbelzijdige plakfolie.

|

Optioneel aan de achterzijde |

| Type materiaal | Acrylaat gegoten (GS) |

| Oppervlakte voorzijde | Glad, glanzend |

| Oppervlakte achterzijde | Glad, glanzend |

| Levertijd | Direct uit voorraad leverbaar |

Sample nodig?

Bestel een sample om materiaal, kleur en afwerking in het echt te beoordelen.

Psssttt....

Losse materialen bestellen?

Wist je dat je onze materialen ook zonder bewerking kan bestellen om zelf te lasersnijden? Neem gauw een kijkje bij Laser Cut Supply.