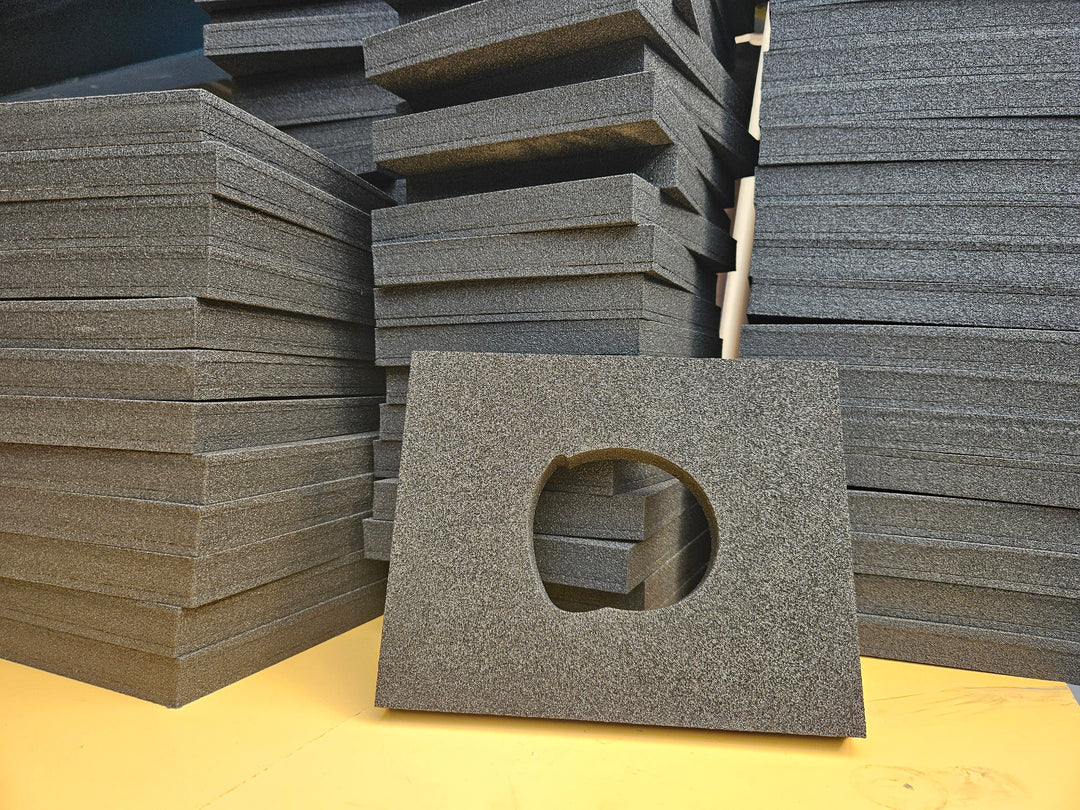

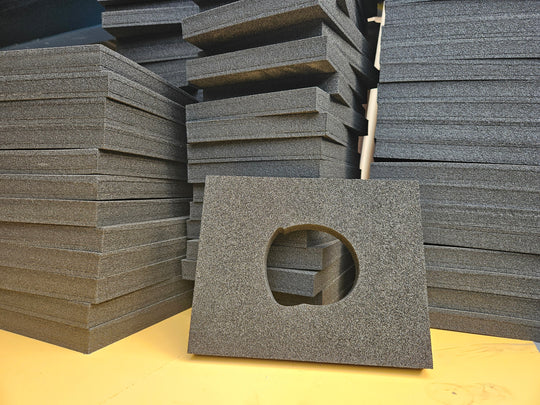

Polyethylene (PE) foam is a material consisting of closed air cells. This ensures that the material offers excellent protection. The foam is about as hard as packaging foam, we also supply a softer variant (soft foam).

Applications

The application area of PE foam is mainly suitcase inlays and to protect objects. In addition, the material is also very suitable for logos, wall ornaments and layered sculptures.

Design considerations

Foam has a relatively large cut, as a rule of thumb the thicker the material the wider the cut. Flat engraving is possible and is relatively deep (1-2 millimeters)

Laser cutting

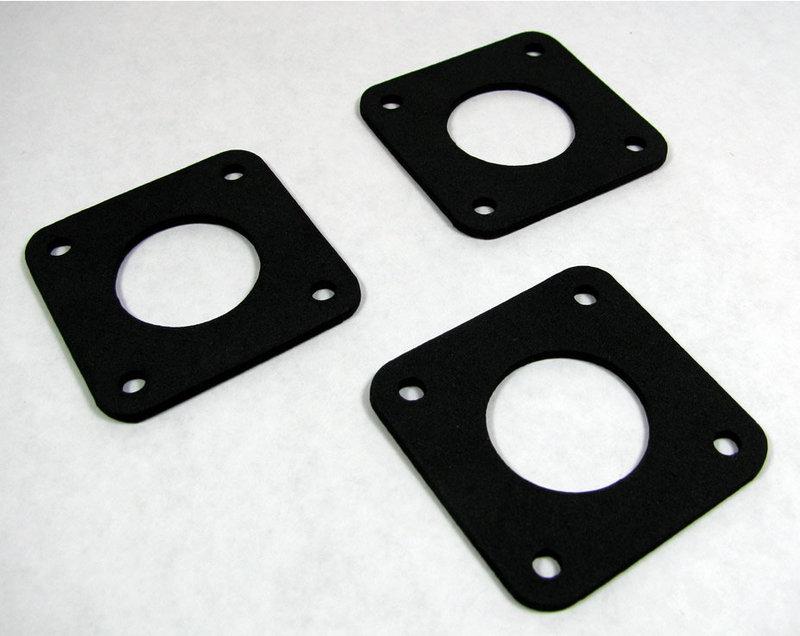

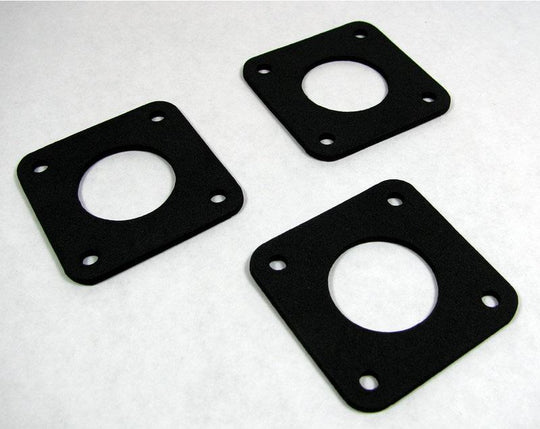

The material retains a clean cut without tarnishing after laser cutting. The cut looks about the same as the material itself but the cut is slightly slanted. The foam is a bit elastic, we try to load the material into the laser as carefully as possible without tension, but it is possible that a part that is "relaxed" deviates a little from the actual size.

Protective film and double-sided adhesive film are not possible. Cut parts may have a little black backlash from the laser bed on the underside of the material.

| Cutting width | 0.6mm (±0.3mm) |

| Smallest shape supplied | 6x6mm |

| Maximum size | 120x60cm (up to 200x120cm on request) |

Post-processing

After laser cutting, PE foam can be processed with a knife or hot knife. The foam can also be painted or glued with spray adhesive or contact adhesive.

Appearance

Hard foam feels soft (for comparison, as soft as mattress foam) and is light gray in color. The cut is colorless and feels the same as unprocessed material.

Technical information

| Characteristic | Value |

| Density | 0.029 gram/cm3 |

| Thickness tolerance | <20% |

| Suitable for outdoor use | No |

Delivery time: Delivery possible within 1-2 working days

Technische gegevens van PE hard foam

| Voordelen | Lichtgewicht maar stijver dan zachtschuim, gesloten-cel en waterafstotend, schok- en trillingsdempend, chemisch resistent, thermisch isolerend, makkelijk te snijden en vormgeven |

| Nadelen | Beperkte hittebestendigheid, matige UV-bestendigheid, lastig te verven, minder stijf dan massieve kunststoffen |

| Goed geschikt voor | Bescherm-inlays en kofferindelingen, verpakkingen, technische pads en dempers, drijfelementen, maquettes en props, sport- en orthese-toepassingen |

| Minder goed geschikt voor | Dragende/structurele onderdelen, langdurig buitengebruik zonder bescherming, toepassingen met hoge temperatuur, zeer fijne scherpe details onder spanning |

| Beschikbare kleuren | Zwart |

| Beschikbare diktes | 5mm, 10mm, 20mm |

| Grootste standaard maat | 120x60cm |

|

Grootste maat op aanvraag

Heb je een project wat groter is dan onze standaard maat?

Vraag een offerte aan. |

200x120cm |

| Snede breedte | 0,5mm |

| Kleinst mogelijke detail (graveren) | 1x1mm |

| Kleinste meegeleverde vorm | 10x10mm |

| Geschikt voor buitengebruik | Ja |

| Dichtheid | 0,06 g/cm³ |

| Lichtdoorlatendheid | Ondoorzichtig |

| Diktetolerantie | 15% |

|

Beschermfolie

Lees hier meer over

beschermfolie.

|

Optioneel voor beide zijden |

|

Dubbelzijdige plakfolie

Lees hier meer over

dubbelzijdige plakfolie.

|

Optioneel aan de achterzijde |

| Type materiaal | Schuim |

| Oppervlakte voorzijde | Grootcellig schuim |

| Oppervlakte achterzijde | Grootcellig schuim |

| Levertijd | Direct uit voorraad leverbaar |

Sample nodig?

Bestel een sample om materiaal, kleur en afwerking in het echt te beoordelen.

Psssttt....

Losse materialen bestellen?

Wist je dat je onze materialen ook zonder bewerking kan bestellen om zelf te lasersnijden? Neem gauw een kijkje bij Laser Cut Supply.